Understanding Polyamide Adhesives

Types of Polyamide Adhesives

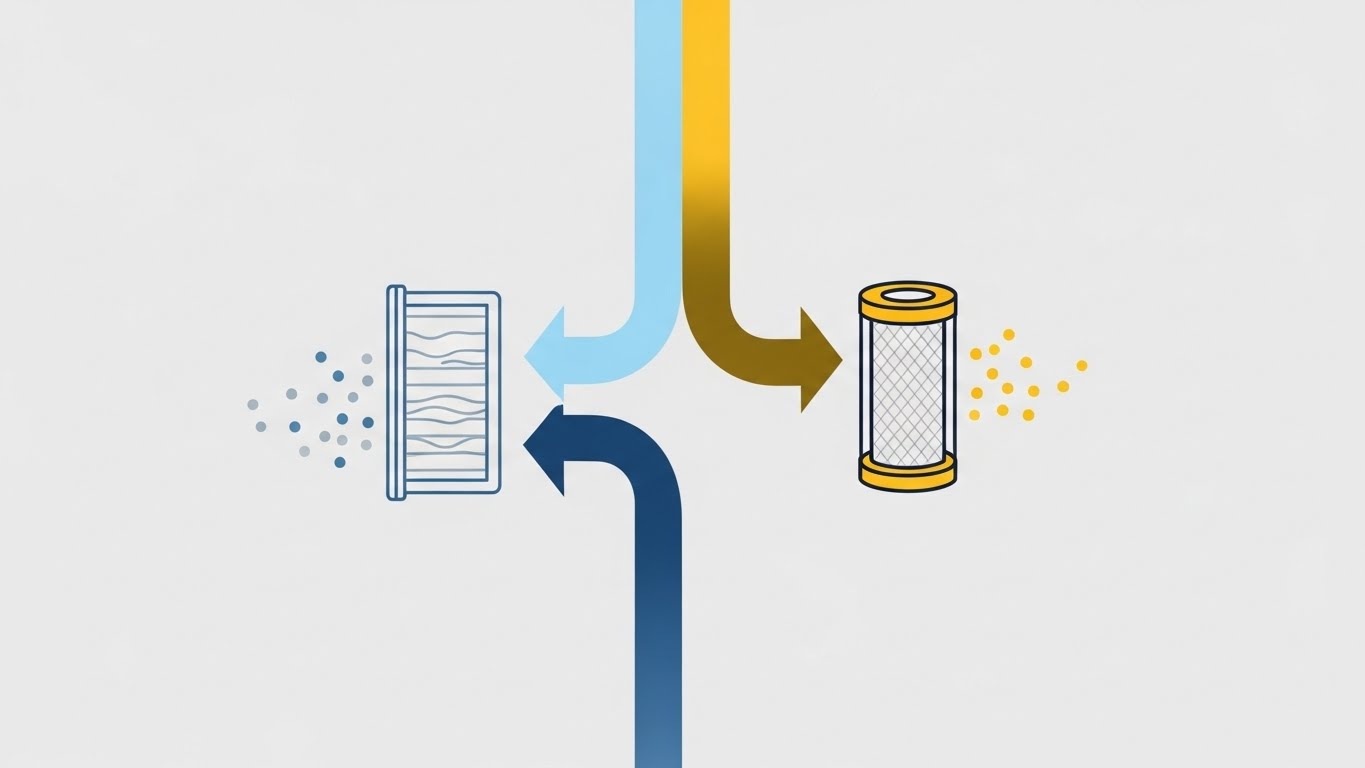

Role in Air & Oil Filters

Application Methods

Importance in Filtration

Latest Trends in Usage

Future Strategies for Innovation

FAQ

Polyamide adhesives are widely used in demanding industrial environments due to their strong bonding properties, thermal resistance, and chemical durability. In air and oil filter manufacturing, these adhesives help maintain structural integrity even under high temperatures, pressure fluctuations, and exposure to oils or airborne contaminants. Their versatility enables reliable bonding for pleated media, end caps, and frame structures, supporting consistent filtration performance.

Polyamide adhesives used in filter production are typically divided into two main categories:

Harden through chemical reactions during or after heat exposure

Suitable for high-load, high-temperature applications

Offer exceptional structural strength

Melt and solidify without further curing

Provide good flexibility and easier processing

Suitable for applications requiring fast production cycles or intricate filter geometry

Both categories are engineered to maintain performance in environments involving high heat, vibration, and chemical exposure, helping filters operate reliably throughout their service life.

Polyamide adhesives are essential for ensuring the durability and function of air and oil filters. Their key roles include:

Bonding pleated filter media to end caps

Maintaining shape integrity under pressure changes

Resisting degradation when exposed to oils, fuels, and airborne contaminants

Supporting filter longevity in high-temperature environments

Their heat resistance, rapid setting capabilities, and compatibility with various substrates make polyamide adhesives a preferred choice in filtration systems where stability and reliability are critical.

Common application techniques for polyamide adhesives in filter manufacturing include:

Covers large surfaces evenly

Ideal for pleated media or broad bonding areas

Provides precise adhesive placement

Suitable for end-cap filling or bead applications

Offers uniform adhesive distribution

Effective for large-scale production lines

Selecting the correct method depends on filter design, production volume, adhesive viscosity, and required bond characteristics. Proper application ensures structural stability and long-term filter performance.

Importance in Filtration

Importance in FiltrationIn filtration systems, reliability is everything. Polyamide adhesives help ensure:

Stable structural bonding over long operating periods

Resistance to oil, fuel, moisture, and elevated temperatures

Reduced risk of delamination or media collapse

Consistent filtration efficiency

By reinforcing vital components, polyamide adhesives help filters withstand demanding industrial, automotive, and HVAC applications, improving equipment efficiency and reducing maintenance costs.

Recent developments in polyamide adhesive usage include:

Shift toward sustainability

More manufacturers are adopting polyamide formulations with reduced emissions and improved energy efficiency during processing.

Greater thermal and chemical resistance

Newer formulations maintain adhesion even under extended exposure to oils, fuels, and high heat.

Fast-curing systems

Increased demand for rapid production cycles encourages the use of polyamides with quicker setting behavior.

Enhanced compatibility with recycled filter materials

Growing environmental regulations are driving innovation toward adhesives that support recyclability and responsible material use.

These trends reflect a broader move toward efficient, sustainable, high-performance filter production.

Future development of polyamide adhesives for filtration is expected to focus on:

Improved heat and chemical durability for longer filter lifespan

Lower application temperatures to reduce energy consumption

Eco-friendly formulations using partially renewable raw materials

Specialized adhesives for advanced filter geometries

Customization for automated, high-speed production lines

These innovations will support more efficient filtration systems while reducing environmental impact across the supply chain.

What are polyamide adhesives?

Polyamide adhesives are thermoplastic or reactive bonding materials known for strong adhesion, heat resistance, and chemical durability, widely used in industrial applications including filter manufacturing.

What types exist?

The two major types are reactive and non-reactive polyamides, differing in curing mechanisms, flexibility, and temperature resistance.

Why are they used in air and oil filters?

Because they withstand high temperatures, pressure, and chemical exposure while maintaining strong structural bonds.

Which application methods are used?

Spray, roll coating, and extrusion methods are common, chosen based on production speed and filter design.

What trends influence their usage today?

Sustainable production, enhanced heat and chemical resistance, faster curing systems, and better compatibility with recyclable materials.

How will they evolve in the future?

Future adhesives will focus on improved durability, sustainability, energy efficiency, and compatibility with automated manufacturing.

Can polyamide adhesives endure extreme environments?

Yes. Polyamide formulations are engineered to maintain bond performance under high temperatures and heavy chemical exposure.