Solution

LPM

Solution

LPM

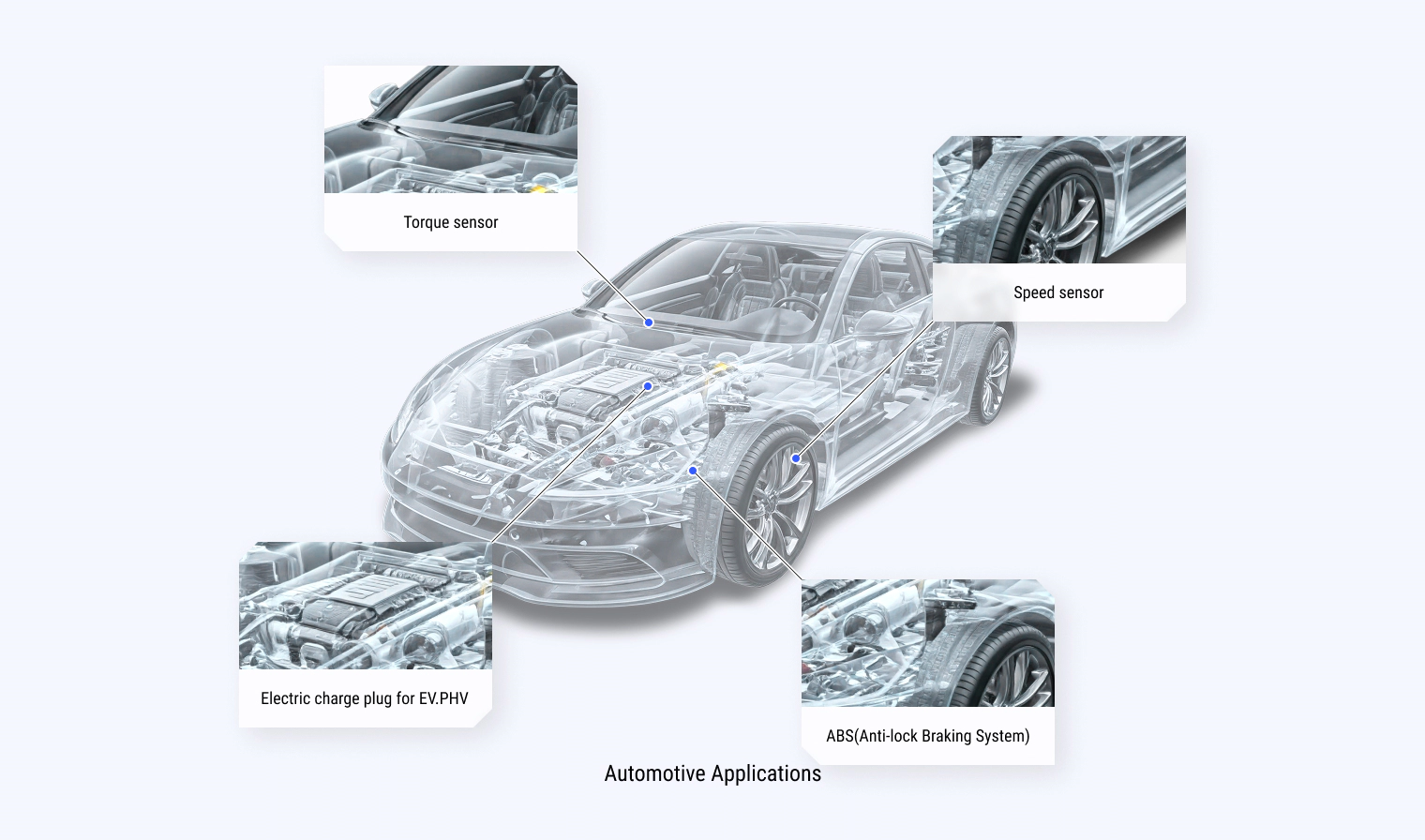

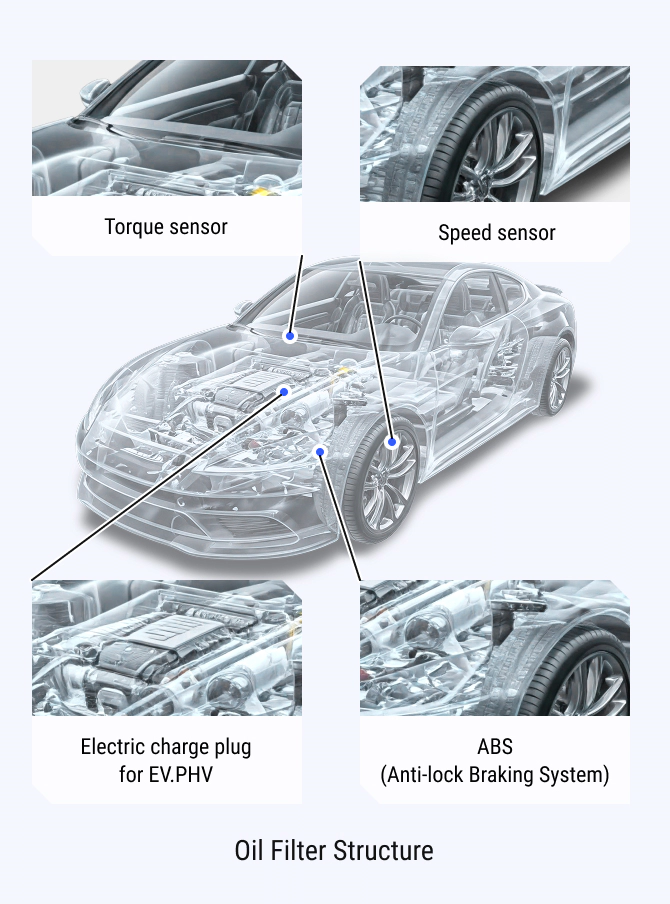

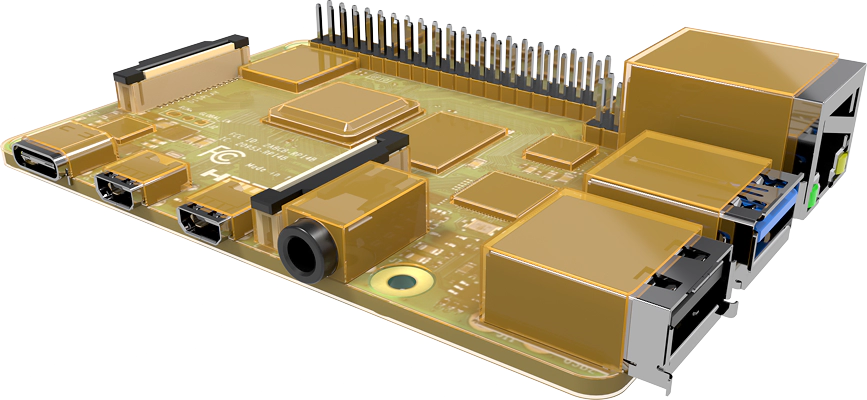

Silverstar Chemicals works with leading dispensing manufacturers to provide customised dispensing solutions, enabling you to achieve better productivity and quality.

Optimised for the low-pressure molding (LPM) process, they provide precise application and high efficiency operation. These dispensers are applicable to a wide range of industries, ensuring high-speed production and reliable adhesion.