Thermoplastic Polymers Overview

Types of Thermoplastic Polymers

Role in Filtration Systems

Selection Criteria for Filters

Manufacturing Methods

Latest Trends in Polymers

Strategies for Optimal Use

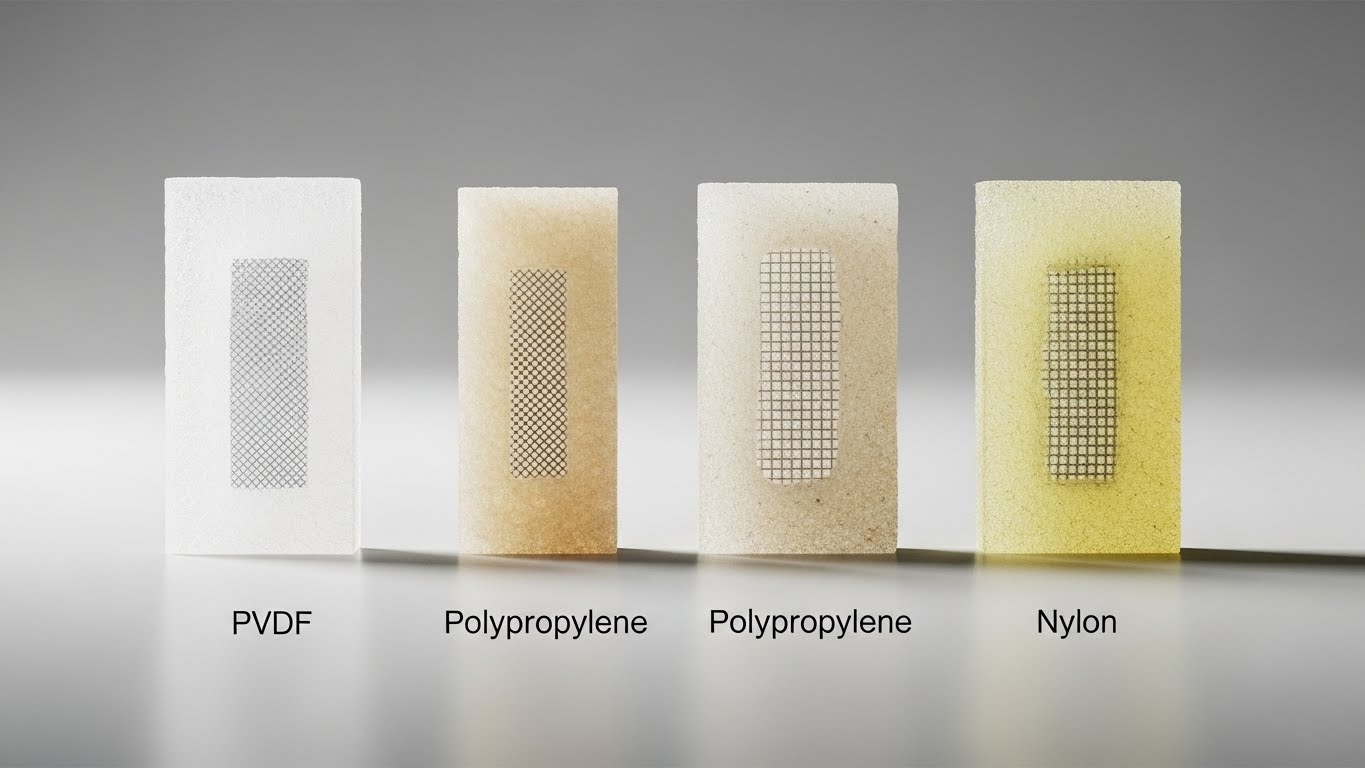

Thermoplastic polymers play a vital role in the performance and durability of modern filtration systems. Each polymer type offers unique characteristics that make it suitable for specific filtration environments.

PTFE provides excellent chemical resistance and thermal stability, ideal for aggressive and high-temperature conditions.

PP is valued for its cost-efficiency and versatility in general-purpose filters.

PVDF offers notable mechanical strength and long-term durability.

Nylon delivers strong abrasion resistance and flexibility, making it suitable for dynamic systems.

Selecting the proper thermoplastic polymer ensures that filters operate efficiently and maintain long service life across varying conditions.

Different thermoplastics offer distinct advantages depending on filtration requirements:

PTFE (Polytetrafluoroethylene)

Exceptional chemical inertness and thermal stability make it ideal for contact with corrosive fluids.

PP (Polypropylene)

A widely used polymer offering high versatility, light weight, and cost-effective performance.

PVDF (Polyvinylidene Fluoride)

Known for mechanical strength, stability, and durability under demanding conditions.

Nylon (Polyamide)

Delivers flexibility, toughness, and strong wear resistance for dynamic or vibration-prone environments.

Understanding these characteristics helps industries design filtration systems optimized for their operating conditions.

Thermoplastic polymers directly influence a filter’s functional reliability. Their role includes:

Supporting pleated media integrity

Providing chemical resistance against fluids and contaminants

Ensuring structural durability under mechanical and thermal stress

Offering flexibility where vibration or movement occurs

Improving long-term filtration efficiency

By selecting the appropriate polymer for a given environment, manufacturers can ensure high filtration performance while minimizing premature failures.

When selecting thermoplastic polymers for filter components, consider:

Chemical Compatibility:

PTFE is ideal for corrosive environments; PP and PVDF perform well with a wide range of fluids.

Thermal Requirements:

PTFE and PVDF maintain stability at elevated temperatures.

Mechanical Strength:

PVDF and Nylon offer superior durability in high-stress applications.

Cost Considerations:

PP provides the most economical option for general filtration.

Flexibility Needs:

Nylon performs well where filters must endure mechanical movement or vibration.

Matching these criteria to environmental and operational demands ensures optimal filter performance.

Different polymers require specific manufacturing techniques to enhance their performance characteristics:

PTFE – Paste extrusion

Enhances chemical resistance, uniformity, and porosity control.

PP – Injection molding

Provides cost-effective shaping for large-scale production.

PVDF – Melt processing

Ensures strong structural integrity and long-term durability.

Nylon – Extrusion

Maximizes flexibility and abrasion resistance.

Choosing the right manufacturing method ensures consistent quality and suitability for each filter design.

Current trends in thermoplastic polymers for filtration include:

Increased adoption of PTFE for extreme chemical and thermal environments

Broader use of PP due to its cost efficiency and compatibility with mass production

Growing demand for PVDF in applications requiring high mechanical strength

Enhanced Nylon formulations for systems needing robust flexibility

Additionally, the industry is shifting toward lightweight, recyclable materials, supporting both performance and sustainability goals.

To maximize filter performance:

Match polymer properties to operating environments.

PTFE for harsh chemicals, PP for general use, PVDF for durable applications, Nylon for dynamic systems.

Verify compatibility with fluid type, temperature, and particulate load.

Use proper manufacturing and processing methods

to maintain material integrity and filtration efficiency.

Evaluate long-term durability through periodic testing and performance monitoring.

Proper selection and usage strategies ensure filters maintain high performance and long service life.

What are thermoplastic polymers used in filtration?

PTFE, PP, PVDF, and Nylon are commonly used due to their chemical resistance, strength, flexibility, and durability.

Why is PTFE preferred for aggressive filtration environments?

Its exceptional chemical resistance and thermal stability allow it to withstand highly corrosive or high-temperature conditions.

What makes polypropylene (PP) suitable for general filtration?

PP is lightweight, versatile, and cost-effective, meeting the needs of many standard filtration applications.

Why choose PVDF for high-demand applications?

PVDF offers excellent mechanical strength and long-term durability.

Why is Nylon used in dynamic systems?

It provides strong abrasion resistance and flexibility, withstanding vibration and movement.

What criteria should be used to select polymers for filters?

Chemical compatibility, thermal stability, mechanical durability, flexibility, and cost.

How are these polymers manufactured?

PTFE via paste extrusion, PP with injection molding, PVDF through melt processing, and Nylon via extrusion.

What trends exist in thermoplastic polymers for filtration?

Greater use of specialized polymers tailored for extreme environments and a shift toward recyclable, efficient materials.