Definition of Temperature-Resistant Adhesives

Types of Adhesives for Filtration

Importance in Filtration Systems

Methods of Application

Latest Trends in Adhesive Technology

Strategies for Effective Use

Future of Adhesives in Filtration

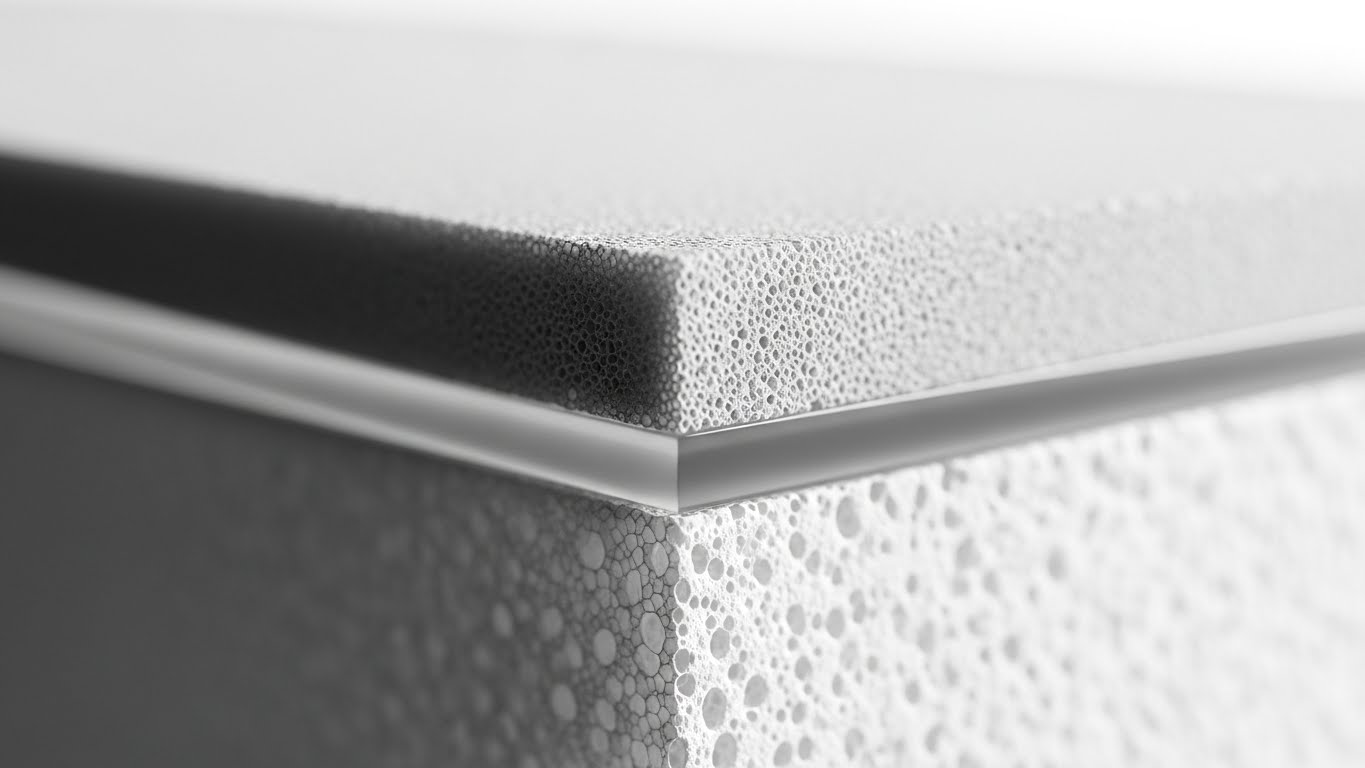

Temperature-resistant adhesives are engineered to maintain bonding performance under extreme thermal conditions. They enable filters to remain structurally stable in both high-temperature and low-temperature environments. These adhesives typically exhibit strong cohesion, thermal stability, and long-term durability—key characteristics required for modern air, gas, and liquid filtration systems that face fluctuating thermal loads.

Adhesives used in filtration must withstand mechanical stress, thermal cycling, and potential chemical exposure. Representative categories include:

Epoxy-based adhesives

Known for high-temperature stability and rigid bonding properties, ideal for structurally demanding filtration components.

Polyurethane-based adhesives

Offer flexibility and resilience, making them suitable for dynamic systems with vibration or movement.

Silicone-based adhesives

Provide excellent thermal resistance and elasticity, maintaining bonds across wide temperature ranges.

Each adhesive type supports specific filtration needs, enabling reliable performance even in extreme working environments.

Importance in Filtration Systems

Importance in Filtration SystemsTemperature-resistant adhesives are fundamental to ensuring that filters maintain:

Structural integrity under thermal expansion and contraction

Reliable bonding between pleated media, end caps, and support structures

Long-term performance despite exposure to hot gases, engine fluids, or industrial air streams

Operational safety by preventing delamination or premature failure

In industries such as transportation, industrial dust collection, and high-temperature processing, these adhesives are essential for maintaining consistent filtration efficiency.

To maximize adhesive performance in filtration manufacturing, proper application methods are critical:

Surface Preparation

All bonding surfaces must be clean, dry, and free of contaminants.

Precise Metering and Mixing

Particularly important for two-part adhesive systems such as epoxies.

Controlled Dispensing

Using bead, spray, or swirl patterns depending on the filter design.

Thermal or Ambient Curing

Ensuring adequate curing conditions based on adhesive chemistry.

Proper application ensures consistent bond strength, improved durability, and reduced failure rates in finished filters.

Recent advancements in adhesive technology for filtration include:

Enhanced thermal resistance formulations

Designed to withstand higher continuous operating temperatures.

Improved chemical resistance

Tailored for exposure to oils, fuels, and corrosive gases.

Low-VOC and eco-friendly compositions

Supporting environmentally conscious manufacturing.

Faster-curing systems

Reducing production cycle times while maintaining high performance.

These trends push filtration systems toward higher reliability and sustainability across demanding industrial applications.

To maximize the effectiveness of temperature-resistant adhesives:

Match adhesive chemistry to temperature and chemical exposure conditions.

Ensure optimal surface preparation for consistent bonding.

Select the appropriate application method for structural or flexible joints.

Validate performance via high-temperature aging, thermal cycling, and mechanical stress tests.

Train production teams on updated adhesive handling and curing procedures.

Implementing these strategies enhances filter longevity and improves operational stability.

The future of temperature-resistant adhesives is shaped by:

Next-generation polymer systems offering higher thermal endurance

Lightweight, energy-efficient filter designs requiring advanced bonding solutions

Sustainability initiatives driving development of safer, low-emission adhesive chemistries

Smart filtration systems where adhesives must integrate with advanced materials and sensors

As filtration demands become more sophisticated, adhesives will play a central role in enabling innovative, durable, and environmentally friendly filter designs.

What are temperature-resistant adhesives?

They are specialized adhesives engineered to maintain bond strength and stability under extreme thermal conditions.

Why are they important in filtration systems?

They ensure filters remain structurally intact and functional despite exposure to high or low temperatures.

What adhesive types are most common in filtration?

Epoxy, polyurethane, and silicone-based adhesives are widely used due to their thermal and mechanical properties.

How are these adhesives applied?

Application involves proper surface preparation, metering, dispensing, and curing based on adhesive chemistry.

What new trends are emerging?

Higher heat resistance, eco-friendly formulations, and faster-curing technologies.

How can adhesive performance be optimized?

By selecting the correct adhesive type, using proper techniques, and conducting validation tests.

What is the future of adhesive technology in filtration?

Advanced polymers, sustainability-driven formulations, and integration with next-gen filtration materials.