Heat shielding adhesives are essential for protecting components and structures exposed to high temperatures. These adhesives serve as thermal barriers, reflecting or insulating against heat to prevent damage and performance degradation. Commonly used in the automotive, aerospace, and electronics industries, they help extend product lifespan and ensure system stability under thermal stress.

Depending on application requirements, heat shielding adhesives come in the following forms:

Tape Type: Ideal for detailed or confined spaces, offering easy application and flexibility.

Sheet Type: Covers large areas efficiently, suitable for flat or broad surfaces needing thermal protection.

Blanket Type: Adaptable to irregular shapes, providing high insulation in environments requiring flexibility.

Heat can cause irreversible damage to critical components, making thermal management essential. Using appropriate heat shielding adhesives offers several benefits:

Automotive: Protects engine compartments and battery enclosures from extreme temperatures.

Aerospace: Ensures high-altitude and high-speed components remain stable under fluctuating heat conditions.

Electronics: Prevents overheating in devices like CPUs, batteries, and power modules, improving safety and longevity.

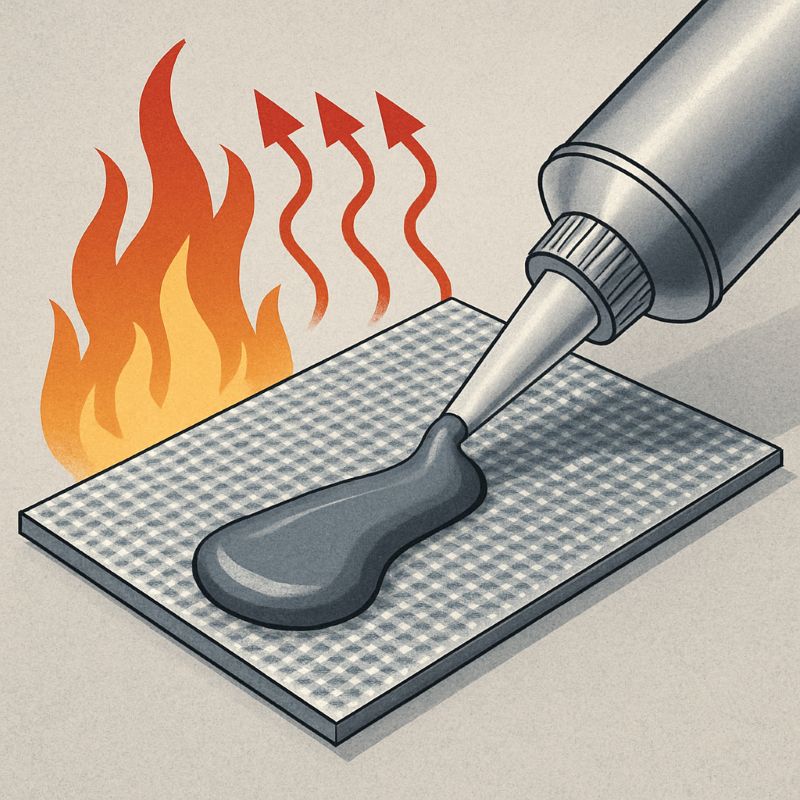

Different methods optimize the effectiveness of heat shielding adhesives depending on surface size and geometry:

Brushing: Suitable for precise applications and small surfaces.

Spraying: Ideal for even distribution across larger surfaces.

Rolling: Efficient for broad or continuous surface coverage.

Choosing the correct method ensures consistent insulation and bonding performance under thermal load.

These adhesives are widely used in the following sectors:

Automotive: Under-hood thermal protection, battery thermal barriers, and EV modules.

Aerospace: Jet engine surroundings, avionics compartments, and structural insulation.

Electronics: Chipsets, wireless charging zones, and high-performance LED modules.

Their high heat resistance and customizable application make them a preferred choice for modern thermal protection.

Current trends in heat shielding adhesive development focus on both performance and sustainability:

Low-VOC, solvent-free formulations

Higher heat resistance with thinner layers

Multifunctional adhesives (thermal + electrical insulation + flame resistance)

These trends are driven by growing demands for energy efficiency, regulatory compliance, and long-term reliability in harsh environments.

To ensure maximum effectiveness:

Select the right form based on the surface and operating temperature.

Prepare bonding surfaces properly—clean, dry, and primed if needed.

Apply using the most suitable method (brush, spray, roll).

Control post-application factors like curing time, exposure to heat, and surface tension.

Proper implementation leads to stronger bonds, longer service life, and safer systems in high-temperature scenarios.

Let me know if you want the next post in this series or prefer a version customized for a specific industry (e.g., EV, aerospace, electronics).