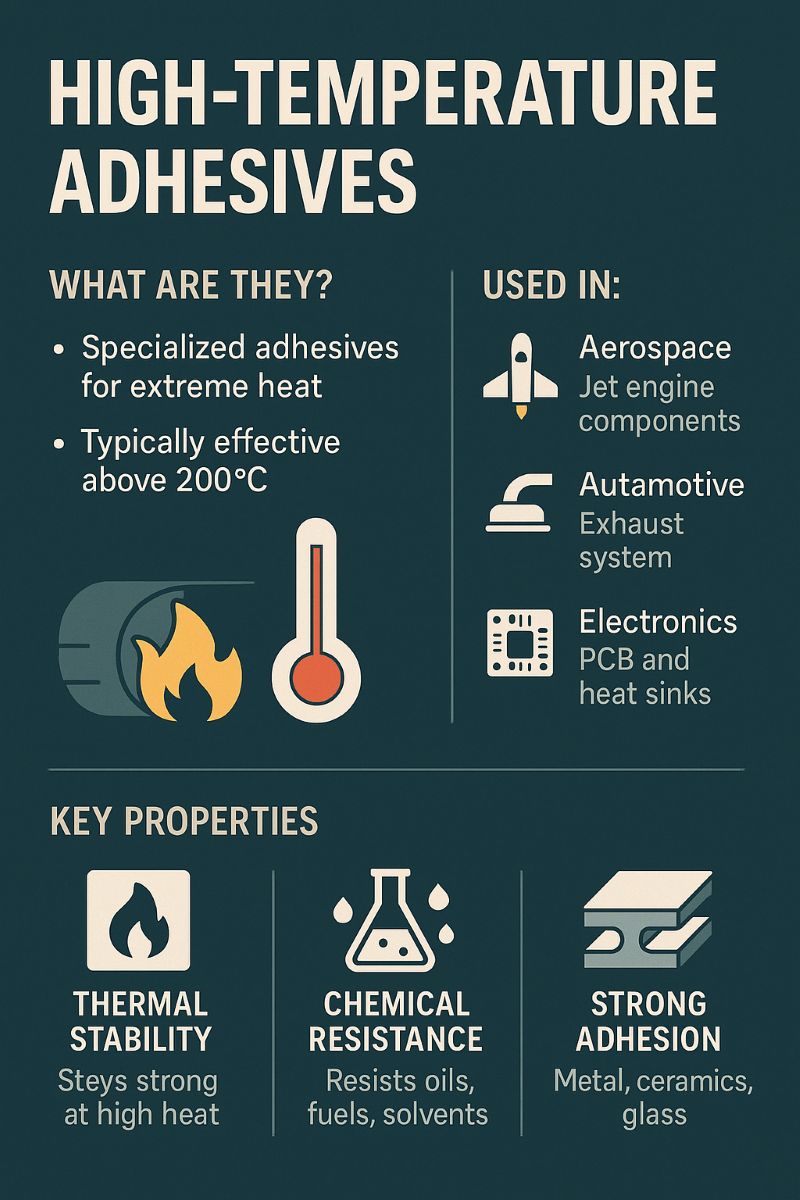

High-temperature adhesives are engineered bonding materials that maintain their strength and integrity under extreme heat conditions. Typically designed to perform beyond 200°C, these adhesives are critical in environments such as aerospace, automotive, and electronics. Their main features include thermal stability, chemical resistance, and strong adhesion, making them reliable for long-term use in harsh conditions.

Several types of high-temperature adhesives are commonly used across industries:

Epoxy-Based Adhesives: Known for high mechanical strength and thermal stability, suitable for structural bonding.

Silicone-Based Adhesives: Offer flexibility and excellent heat resistance, ideal for parts exposed to vibration or movement.

Ceramic-Based Adhesives: Provide superior thermal insulation and electrical resistance, commonly used in high-voltage or high-temperature zones.

Each type has unique characteristics that cater to specific application needs in industrial and electronic assemblies.

The effectiveness of a high-temperature adhesive is determined by its ability to retain essential properties under heat. These include:

Bonding Strength: Ensures the adhesive holds components together during thermal stress.

Thermal Stability: Prevents softening, cracking, or degradation at high temperatures.

Chemical Resistance: Protects against fuel, oil, and corrosive substances in aggressive environments.

Choosing adhesives with these traits helps maintain system safety and longevity.

To evaluate performance, adhesives are subjected to standardized tests, including:

Peel Tests: Measure resistance to separation between bonded layers.

Shear Strength Tests: Assess resistance to forces parallel to the bond line.

Thermal Cycling Tests: Simulate repeated heating and cooling to test long-term durability.

These testing methods help validate the adhesive’s suitability for high-temperature operations.

Recent developments in high-temperature adhesive technology focus on:

Thermal Conductivity Enhancement: Enables adhesives to dissipate heat more efficiently in electronics.

Eco-Friendly Formulations: Reduces environmental impact while maintaining industrial performance.

Self-Healing Capabilities: Offers the ability to repair microcracks and prolong service life.

These innovations are addressing both environmental regulations and increasing demands for efficiency and resilience.

When selecting a high-temperature adhesive, consider the following:

Operating Temperature Range: Choose an adhesive with a heat tolerance higher than the expected thermal load.

Material Compatibility: Ensure proper bonding with the substrates used (metal, plastic, ceramic, etc.).

Environmental Conditions: Evaluate exposure to moisture, chemicals, and mechanical stress.

Curing Method: Determine if fast-setting or oven-curing adhesives are more appropriate for the process.

Proper selection leads to improved reliability, safety, and reduced failure rates in production and operation.

These adhesives are used across various sectors:

Aerospace: For bonding parts near engines or exhausts that experience extreme heat.

Automotive: In powertrains, under-hood assemblies, and exhaust systems.

Electronics: To secure and protect heat-generating components like resistors and CPUs.

Industrial Equipment: In manufacturing tools exposed to continuous thermal cycles.

Their ability to endure harsh environments makes them indispensable for modern high-performance systems.