Understanding Hot Melt Adhesives

Types of Hot Melt Adhesives

Importance in Filter Manufacturing

Application Methods for Filters

Latest Trends in Adhesive Use

Strategies for Adhesive Selection

Future of Adhesives in Filtration

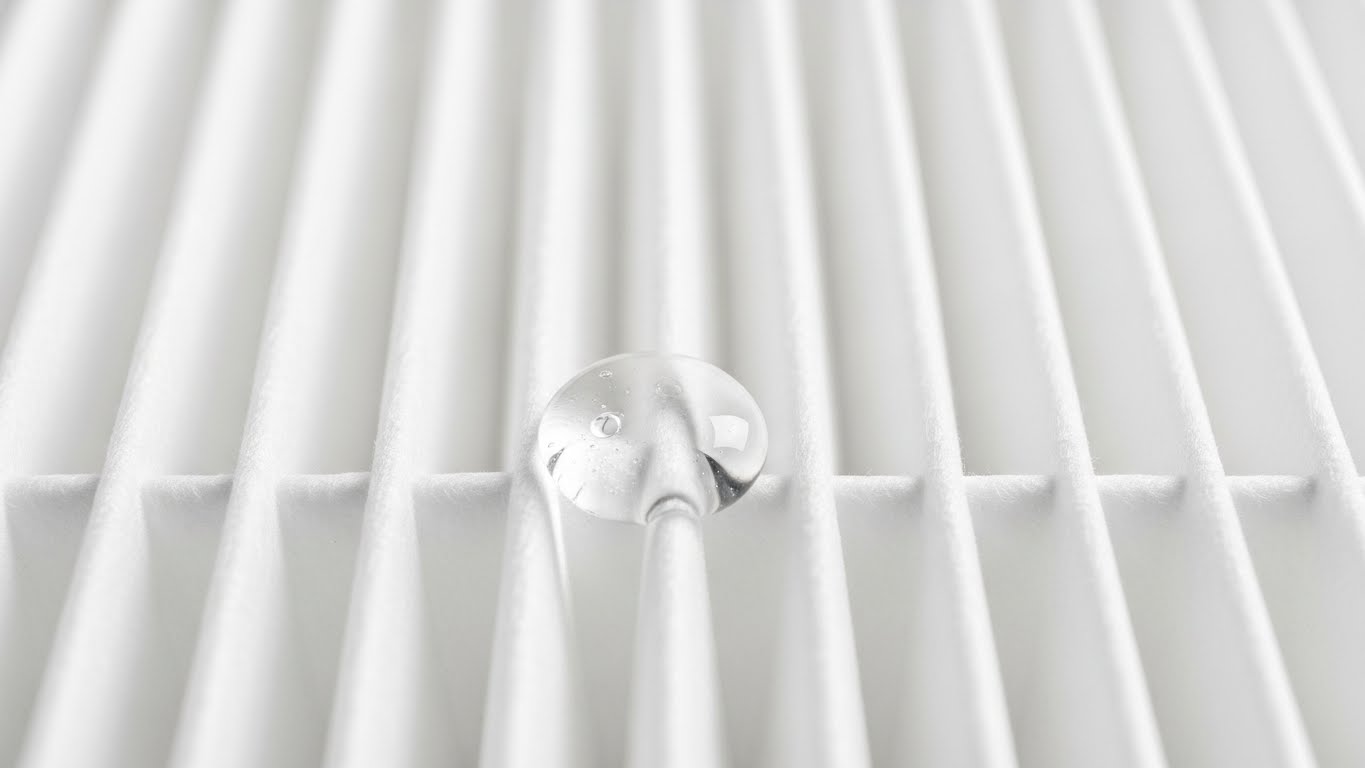

Hot melt adhesives play a crucial role in filter manufacturing due to their efficiency, speed, and versatility. These thermoplastic adhesives are applied in a molten state and solidify upon cooling, forming strong bonds within a short cycle time. This characteristic makes them well suited for high-speed production lines used in air, oil, and liquid filter manufacturing. By enabling consistent bonding between filter media, end caps, and frames, hot melt adhesives contribute directly to filter durability, dimensional stability, and long-term performance.

Hot melt adhesives used in filter manufacturing can be classified based on their polymer composition and performance characteristics.

EVA-based hot melts

Widely used for general filter assembly due to their balanced flexibility, adhesion, and cost efficiency.

Polyolefin-based hot melts

Offer improved resistance to heat, moisture, and chemicals, making them suitable for filters exposed to harsher operating environments.

Polyamide-based hot melts

Known for high temperature resistance and strong mechanical strength, often applied in filters requiring long service life under thermal stress.

Pressure-sensitive hot melts

Remain tacky at room temperature and are used in applications requiring repositioning or temporary fixation during assembly.

Selecting the appropriate type depends on operating temperature, chemical exposure, and filter design requirements.

In filter manufacturing, hot melt adhesives are essential for ensuring structural integrity and production efficiency. Their fast setting behavior supports continuous, automated assembly processes, reducing cycle times and minimizing downtime. Strong and uniform bonding prevents air or fluid bypass, which is critical for maintaining filtration efficiency. By securing filter components reliably, hot melt adhesives help extend product lifespan and ensure consistent performance in real-world operating conditions.

The performance of hot melt adhesives is closely linked to the application method used during filter assembly.

Roll coating

Provides uniform adhesive layers on flat or continuous substrates, ideal for high-volume production.

Spray application

Allows flexible coverage of complex geometries and irregular surfaces, commonly used in pleated filter designs.

Extrusion (bead application)

Enables precise adhesive placement, supporting structural reinforcement at critical bonding points.

Choosing the correct application method ensures optimal adhesive distribution, consistent bond quality, and stable filter performance.

Recent trends in hot melt adhesive use for filtration focus on performance enhancement and sustainability. Manufacturers are increasingly adopting low-emission formulations to support environmentally responsible production. There is also growing demand for adhesives with higher thermal resistance to accommodate filters used in high-temperature or high-load systems. In addition, advances in automated dispensing and process control technologies are improving application accuracy, reducing material waste, and increasing overall manufacturing efficiency.

Selecting the right adhesive for filter manufacturing requires a systematic evaluation of several factors:

Operating temperature and thermal cycling conditions

Chemical exposure from air, oil, or process fluids

Compatibility with filter media and structural components

Required production speed and application method

Aligning adhesive properties with these conditions helps prevent premature bond failure and ensures long-term filter reliability.

The future of adhesives in filtration is closely tied to advances in material science and manufacturing automation. Hot melt adhesives are expected to evolve toward higher performance, improved sustainability, and greater process integration. Developments such as energy-efficient curing, enhanced durability, and compatibility with recyclable filter materials will play an important role. As filtration systems become more demanding, adhesives will continue to be a key enabler of reliable, high-efficiency filter solutions.

What are hot melt adhesives?

They are thermoplastic adhesives applied in a molten state that solidify upon cooling, forming strong and fast-setting bonds.

Which hot melt adhesives are used in filter manufacturing?

Common types include EVA-based, polyolefin-based, polyamide-based, and pressure-sensitive hot melts.

Why are hot melt adhesives important for filters?

They ensure strong bonding, support high-speed production, and help maintain filtration efficiency by preventing bypass.

What application methods are commonly used?

Roll coating, spray application, and extrusion are widely used depending on filter design and production requirements.

What trends are influencing adhesive selection?

Key trends include low-emission formulations, higher temperature resistance, and increased use of automated application systems.

How should manufacturers choose the right adhesive?

By evaluating operating conditions, material compatibility, and production constraints before selecting an adhesive type.

What is the future outlook for filtration adhesives?

Continued innovation toward sustainable, high-performance, and automation-friendly adhesive solutions.