Definition of Flame Retardant Adhesives

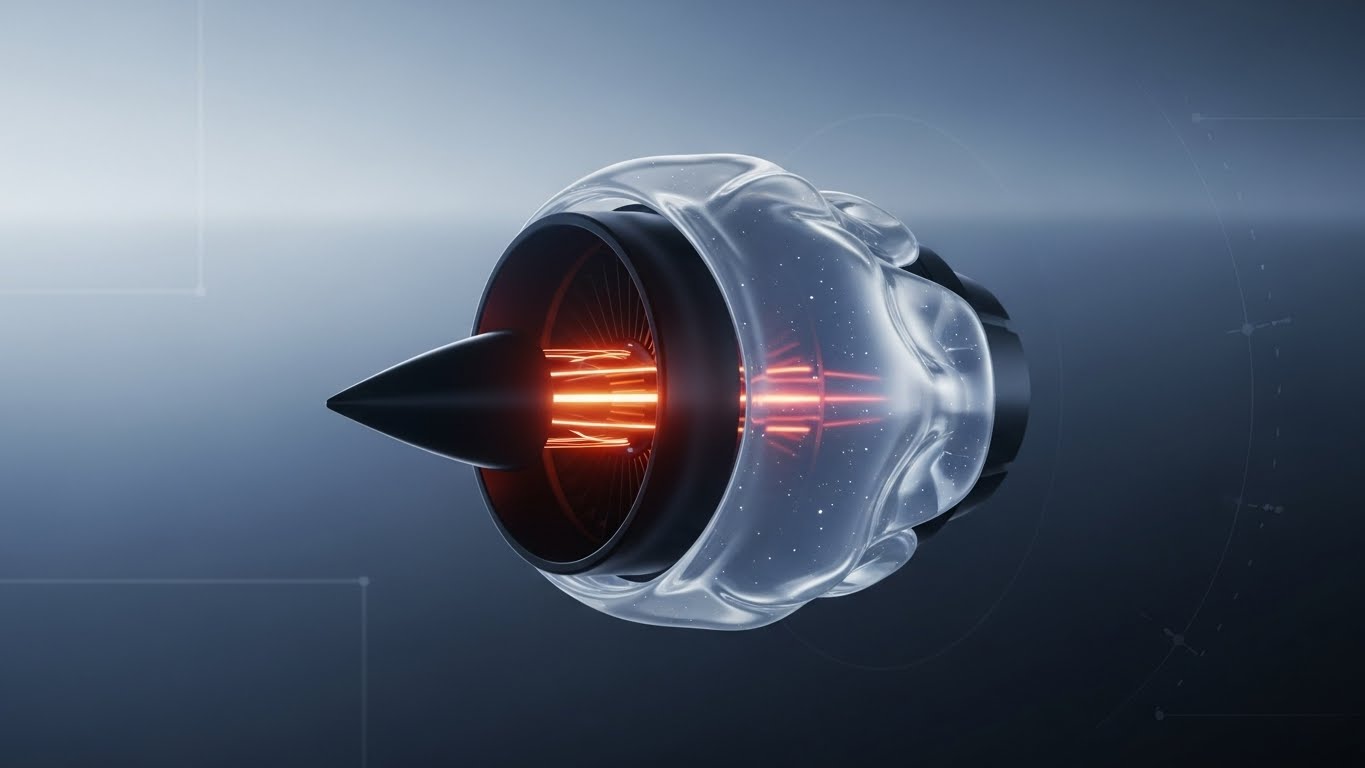

Types of Aerospace Adhesives

Importance in Aerospace Industry

Methods of Application

Latest Trends in Adhesive Technology

Strategies for Enhanced Safety

Future Prospects in Aerospace

Flame retardant adhesives are specialized bonding materials engineered to resist ignition, limit flame propagation, and maintain bonding performance when exposed to elevated temperatures. In aerospace applications, these adhesives are designed to preserve structural integrity under thermal stress while supporting overall fire safety requirements. Their formulation typically focuses on controlled combustion behavior, reduced heat release, and stability during prolonged heat exposure. By meeting stringent fire-performance criteria, flame retardant adhesives play a critical role in protecting passengers, equipment, and structural components in aviation environments.

Aerospace adhesives encompass a range of material classes, each optimized for specific performance requirements. Flame retardant variants are commonly developed within epoxy-based, silicone-based, and hybrid polymer systems. Epoxy-based formulations are valued for their mechanical strength and thermal stability, while silicone-based systems offer flexibility and resistance to thermal cycling. Hybrid formulations aim to balance strength, flexibility, and fire resistance. These adhesive categories are selected based on operating temperature, mechanical load, environmental exposure, and fire-safety expectations rather than on product-specific branding.

In the aerospace industry, flame retardant adhesives are essential for managing fire risk while maintaining structural performance. Aircraft interiors, electronic housings, insulation systems, and structural assemblies all rely on bonded joints that must remain stable during fire-related incidents. Adhesives used in these environments are expected to contribute minimally to flame spread, smoke generation, and heat release. By integrating flame retardant adhesive systems into aircraft design, manufacturers can enhance safety margins, support regulatory compliance, and improve long-term reliability of aerospace components.

Application of flame retardant adhesives in aerospace manufacturing requires precision and process control. Common application methods include controlled dispensing, brushing for localized bonding, and automated systems for complex assemblies. Uniform adhesive thickness, proper surface preparation, and controlled curing conditions are critical to achieving consistent performance. Application methods are selected based on component geometry, production scale, and required bond-line accuracy. These process considerations are integral to ensuring that the adhesive performs as intended under thermal and mechanical stress.

Recent trends in aerospace adhesive technology focus on improving fire performance while maintaining lightweight design and mechanical efficiency. Advances in polymer chemistry are enabling formulations with enhanced thermal stability, reduced smoke emission, and improved resistance to flame propagation. There is also increasing emphasis on reducing hazardous substances and improving environmental profiles without compromising safety. Additionally, digital process control and automated application technologies are becoming more prevalent, supporting higher consistency and traceability in aerospace adhesive bonding.

Enhancing safety through flame retardant adhesives requires a systematic strategy centered on material selection, design integration, and validation testing. Engineers prioritize adhesive systems with predictable fire behavior, stable mechanical properties at elevated temperatures, and compatibility with aerospace substrates. Process optimization, including surface treatment and curing control, further contributes to safety performance. Continuous evaluation through standardized fire and thermal testing ensures that adhesive systems meet evolving safety expectations throughout the aircraft lifecycle.

The future of aerospace adhesive technology will increasingly emphasize integrated fire safety, structural efficiency, and sustainability. Flame retardant adhesives are expected to evolve alongside next-generation aircraft designs, supporting higher operating temperatures, lighter structures, and more complex assemblies. Innovations in material science are likely to produce adhesives with improved fire resistance, lower environmental impact, and greater design flexibility. As aerospace systems continue to advance, flame retardant adhesives will remain a foundational element in ensuring safe, reliable, and efficient aircraft structures.

What are flame retardant adhesives?

Flame retardant adhesives are bonding materials designed to resist ignition and limit flame spread when exposed to high temperatures.

Why are flame retardant adhesives important in aerospace?

They help reduce fire risk while maintaining structural integrity in aircraft components exposed to thermal stress.

What types of adhesive systems are used in aerospace?

Common systems include epoxy-based, silicone-based, and hybrid polymer adhesives, selected based on performance requirements.

How are flame retardant adhesives applied in aircraft manufacturing?

They are applied using controlled dispensing, brushing, or automated systems to ensure consistent bonding quality.

What trends are shaping aerospace adhesive technology?

Key trends include improved fire performance, reduced smoke emission, lightweight design support, and advanced application automation.

How can aerospace manufacturers enhance adhesive safety?

By selecting appropriate materials, optimizing application processes, and validating performance through standardized testing.

What is the future role of flame retardant adhesives in aerospace?

They will remain essential for supporting advanced aircraft designs, higher safety standards, and long-term reliability.