Understanding Low Pressure Molding

Types of Molding Machines

Importance for DIY Enthusiasts

Effective Molding Methods

Latest Trends in Molding

Strategies for DIY Projects

Low pressure molding (LPM) is a safe and efficient technique for encapsulating electronic components, particularly valuable for hobbyists and DIY engineers. It operates at lower temperatures and pressures than traditional molding, reducing the risk of damage to delicate parts. This process helps create reliable seals that protect electronics from moisture, dust, and vibration, all while being accessible enough for use in home workshops.

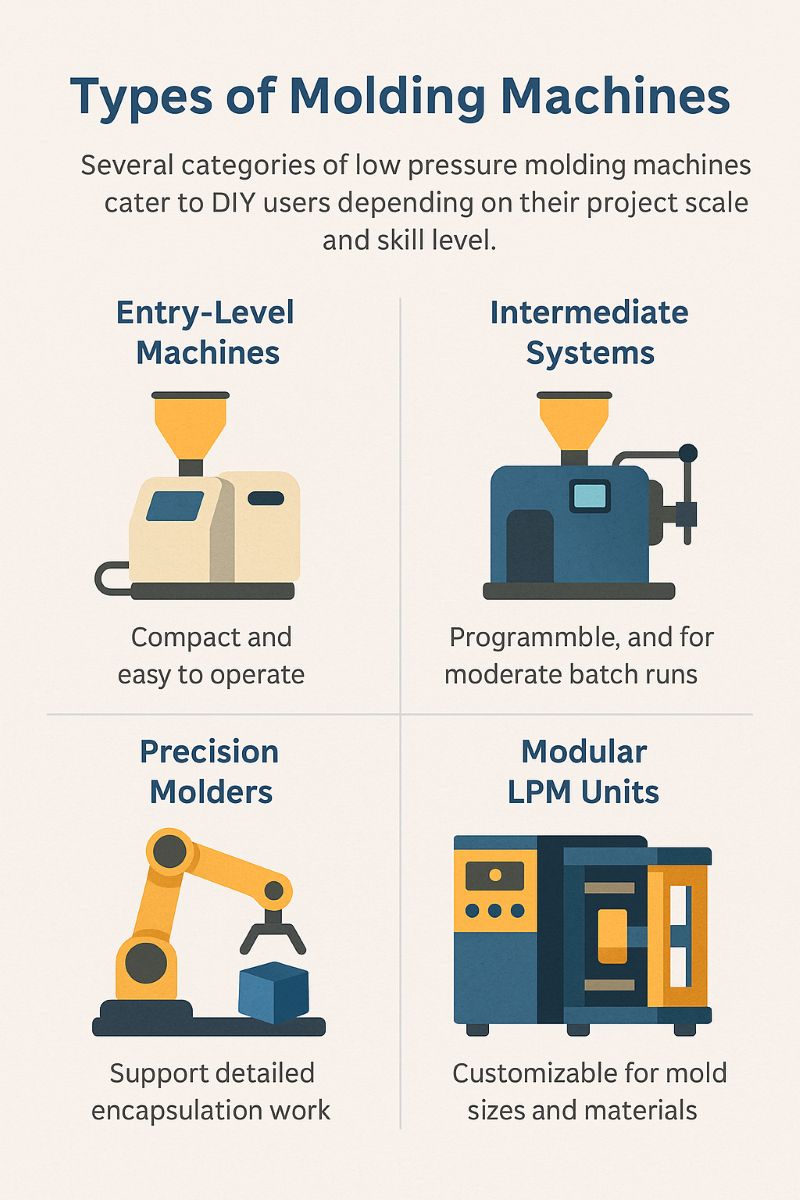

Several categories of low pressure molding machines cater to DIY users depending on their project scale and skill level:

Entry-level machines are compact and easy to operate, suitable for learning basic molding procedures.

Intermediate systems offer programmable controls and allow for moderate batch runs.

Precision molders support detailed encapsulation work for complex shapes.

Modular LPM units can be customized for different thermoplastic materials and mold sizes.

Each type enables hobbyists to explore different molding tasks, from basic wire sealing to advanced electronic module protection.

For hobbyists working with sensors, microcontrollers, or handmade devices, low pressure molding enhances both the functionality and durability of their creations. It simplifies the task of protecting circuit boards and connectors from environmental damage. Since the process minimizes thermal and mechanical stress, it allows for repeated experimentation without damaging delicate components. Incorporating LPM into DIY projects opens new creative avenues while maintaining professional-level protection.

Mastering effective LPM methods requires aligning your machine's capability with the needs of your specific application:

Basic sealing techniques involve using thermoplastic sticks or pellets to enclose connectors or small boards.

Mold insert alignment ensures that parts stay in position during the molding process.

Step-controlled heating profiles help maintain optimal flow without overheating sensitive elements.

Two-stage encapsulation can provide added protection for critical areas.

Practicing these methods not only yields better results but also strengthens your understanding of the molding process as a whole.

Recent developments in the DIY molding space include:

Compact LPM systems designed for personal workbenches

Open-source control modules for customizing molding parameters

Eco-friendly thermoplastics for safe and sustainable experimentation

Low-volume molds produced via 3D printing, reducing setup costs

These trends are making LPM more accessible and appealing to creative individuals looking to integrate professional-level fabrication techniques into their home labs.

A strategic approach to DIY LPM projects involves the following:

Choose a machine that fits your technical experience and project complexity

Plan the mold design in advance, especially for multi-component builds

Use compatible thermoplastic materials for the substrate and environmental conditions

Conduct small batch tests to fine-tune process settings

Keep a log of material behavior, temperature settings, and outcomes for repeatability

By applying these strategies, you can ensure both the aesthetic quality and structural reliability of your finished products.