Understanding Filter Adhesives

Types of Innovative Adhesives

Importance of Adhesive Efficiency

Methods to Enhance Durability

Latest Trends in Adhesive Tech

Strategies for Improved Adhesion

Future of Filter Adhesives

Frequently Asked Questions (FAQ)

Filter adhesives play a crucial role in maintaining the structural integrity and performance of filtration systems. These bonding agents securely fasten various components such as end caps, media packs, and sealing frames, allowing filters to function effectively under high pressure and temperature variations. Today’s advanced adhesives offer high mechanical strength, chemical resistance, and adaptability to various substrates—making them indispensable in modern filtration design and manufacturing.

Several types of filter adhesives are widely used for their specialized properties:

Polyurethane-based adhesives offer excellent flexibility and resistance to environmental stress, making them suitable for dynamic or vibrating systems.

Epoxy-based adhesives are favored for their strong chemical resistance and high bonding strength, ideal for industrial filters.

Silicone-based adhesives deliver superior thermal stability, perfect for high-temperature or fluctuating conditions.

Fast-curing multipurpose adhesives are commonly used where production speed and versatility are priorities.

By selecting the right formulation based on application requirements, manufacturers can greatly improve filter reliability and service life.

Adhesive efficiency directly impacts the performance of the entire filtration system. A high-efficiency adhesive ensures consistent bonding, minimizes the risk of leakage, and maintains structural cohesion over time. Efficient adhesives also support ease of processing, reducing production time and material waste. With the growing need for robust filtration across industries—from automotive to HVAC—efficient bonding solutions are more critical than ever.

Improving adhesive durability involves a combination of chemical formulation and application technique:

Formulation Optimization: Selecting adhesives engineered for abrasion, fluid exposure, or extreme temperatures.

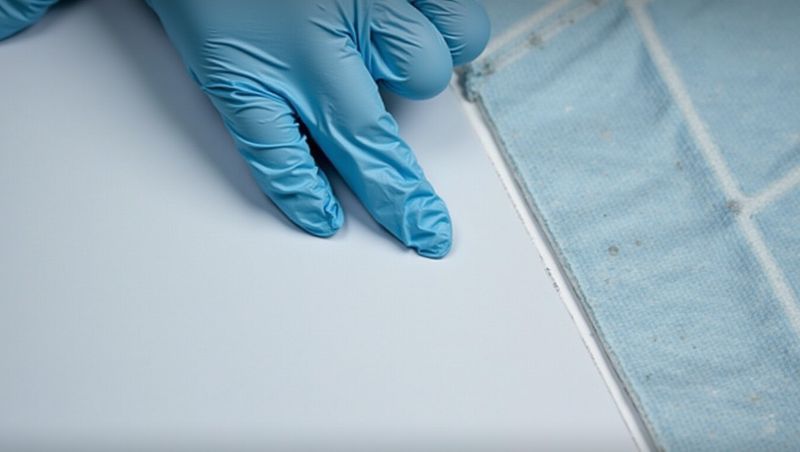

Precise Application: Using automated systems or well-calibrated manual techniques to ensure consistent bond lines.

Surface Treatment: Priming or cleaning bonding surfaces to enhance adhesion.

Curing Control: Ensuring correct temperature, pressure, and time parameters for full polymerization.

Such methods ensure that adhesives maintain their integrity even under mechanical stress, vibration, or thermal cycling.

The adhesive industry for filtration is witnessing rapid innovation. Key trends include:

Eco-conscious formulations: Adhesives with reduced VOCs and higher recyclability.

Faster curing times: For increased throughput in mass production.

Hybrid technologies: Combining the flexibility of polyurethane with the strength of epoxies.

Smart adhesives: Responsive to environmental changes or wear conditions.

These advancements aim to improve both the performance and sustainability of filtration systems in line with modern manufacturing goals.

To enhance bonding effectiveness in filter production:

Choose the right adhesive chemistry based on material compatibility and end-use conditions.

Improve surface preparation with cleaning, roughening, or priming to increase bonding area.

Standardize application methods through robotic or precision dispensing tools.

Train operators to ensure consistency and reduce variability in bonding outcomes.

Adopting these strategies helps reduce defects, extend product lifespan, and optimize overall system reliability.

The future of filter adhesives lies in customization, sustainability, and performance optimization. With increasing demands in filtration—especially for air purification, water treatment, and electric vehicle systems—adhesives must adapt to new substrates, regulations, and performance thresholds. Future developments are likely to emphasize:

Bio-based adhesive alternatives

Enhanced resistance to aggressive chemicals or nanoparticles

Predictive bonding technologies integrated with IoT systems

Rapid prototyping-friendly formulations for agile product development

As the filtration industry evolves, so too must the adhesives that hold its components together.

Q1. What are filter adhesives and why are they important?

Filter adhesives are bonding agents used to assemble components within a filter. They ensure durability, tight sealing, and reliable operation under stress.

Q2. What types of adhesives are commonly used in filters?

Common types include polyurethane (flexibility), epoxy (chemical resistance), silicone (heat stability), and fast-curing multipurpose adhesives for speed and adaptability.

Q3. Why does adhesive efficiency matter?

Efficient adhesives minimize leakage and mechanical failure, reducing maintenance needs and extending filter lifespan.

Q4. How can I enhance the durability of filter adhesives?

Optimize the adhesive formulation, apply it with precision, and ensure proper surface treatment and curing.

Q5. What are the current trends in adhesive technology for filters?

Trends include sustainable formulations, faster curing processes, hybrid chemistries, and intelligent adhesives that adapt to their environment.

Q6. How can I improve adhesion in my filter manufacturing process?

Use adhesives tailored to your materials, ensure surfaces are clean and properly prepped, and apply using standardized techniques.

Q7. What is the future of adhesives in the filtration industry?

Future adhesives will focus on higher performance, eco-friendliness, and integration with digital manufacturing systems for smarter production.

Q8. What are some tips for selecting the right filter adhesive?

Consider operating conditions, material compatibility, processing speed, regulatory compliance, and total lifecycle cost.