Defining Industrial Adhesives

Types of Industrial Adhesives

Importance of Adhesive Selection

Methods for Adhesive Application

Latest Trends in Adhesive Technology

Strategies for Adhesive Testing

Sustainability in Adhesive Use

Frequently Asked Questions (FAQ)

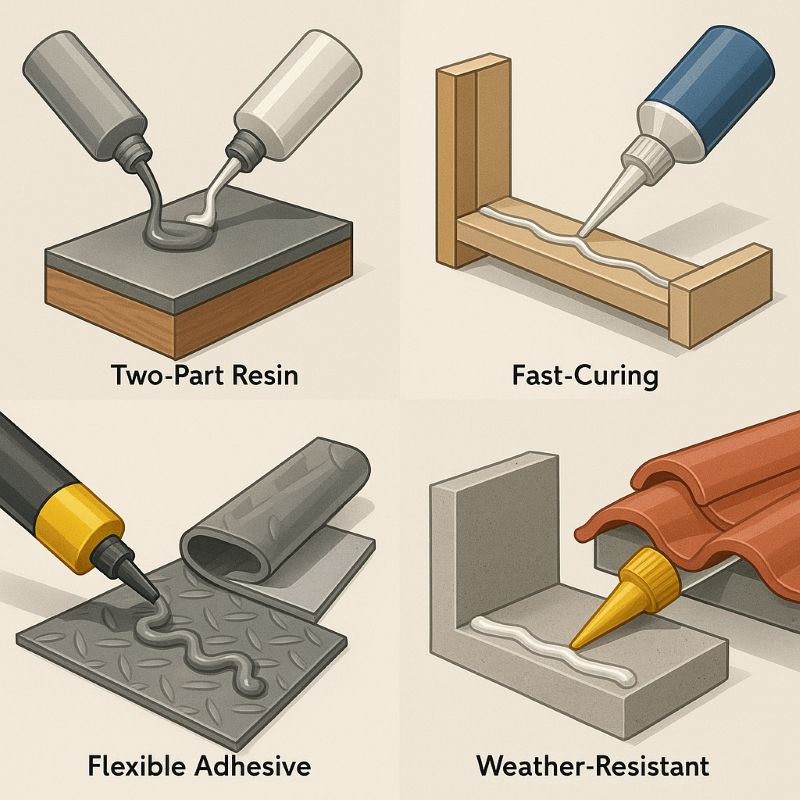

Industrial adhesives are specialized bonding agents engineered for use in manufacturing, assembly, and construction. These adhesives are designed to provide strong, durable bonds across a range of materials and conditions. Common types include two-part resins for structural bonding, fast-curing adhesives for quick assembly, flexible adhesives for materials under movement, and weather-resistant formulations for outdoor applications. Choosing the correct adhesive ensures reliability, safety, and operational efficiency in any industrial setting.

Selecting the appropriate industrial adhesive depends on application-specific demands. Key types include:

Epoxy adhesives: Known for high strength and chemical resistance, ideal for structural bonding.

Cyanoacrylate adhesives: Fast-curing solutions best suited for quick repairs and precision bonding.

Polyurethane adhesives: Provide a balance of flexibility and toughness, accommodating vibration and movement.

Silicone adhesives: Offer strong performance in moisture-rich or high-temperature environments.

Each adhesive type is formulated for specific performance characteristics, ensuring proper compatibility with substrates and end-use conditions.

The correct adhesive selection plays a vital role in project performance and durability. Industrial applications often involve unique requirements—such as extreme temperatures, chemical exposure, or structural load—that demand tailored bonding solutions. Selecting an adhesive based on these criteria reduces the risk of failure, enhances safety, and optimizes cost-efficiency. Key considerations include:

Material compatibility

Curing time and strength

Environmental exposure

Load-bearing needs

Understanding these parameters leads to more consistent and long-lasting outcomes.

Proper adhesive application is critical to achieving optimal bond performance. Common industrial methods include:

Brush or roller application: Used for controlled spreading across large surfaces.

Spray systems: Ideal for high-volume production, offering even coverage with minimal waste.

Cartridge dispensers: Provide precise and clean application for small-scale or detailed work.

Automated dispensing systems: Enable high-speed, repetitive operations with minimal human error.

Each method should be matched to the adhesive type and job requirement to ensure uniform bonding and process efficiency.

Recent advancements in adhesive technology focus on enhancing performance while improving environmental safety. Major trends include:

Low-VOC and solvent-free formulations to meet environmental regulations.

Faster curing adhesives that reduce downtime and energy consumption.

Smart adhesives that signal curing completion via color change, improving process accuracy.

Hybrid technologies that combine strength, flexibility, and sustainability.

These innovations support evolving industrial needs, promoting efficiency and environmental responsibility without sacrificing performance.

Testing adhesives before full-scale implementation helps prevent failure and ensure compatibility. Recommended testing strategies include:

Peel strength and shear testing to evaluate bonding under stress.

Environmental simulations (e.g., heat, moisture, chemicals) to test durability.

Substrate-specific trials to confirm adhesion to required materials.

Implementing proper testing protocols ensures adhesives perform as intended under real-world operating conditions and reduces costly rework.

Eco-conscious adhesive selection is becoming essential across industries. Sustainable adhesive practices include:

Using low-VOC or solvent-free adhesives to reduce emissions.

Sourcing from suppliers with environmentally responsible manufacturing practices.

Selecting recyclable or biodegradable packaging to reduce waste.

Integrating adhesives that require lower application temperatures, thereby conserving energy.

Incorporating sustainability into adhesive selection supports both compliance and brand value while fostering long-term environmental benefits.

What are the main types of industrial adhesives?

They include epoxy (for structural strength), cyanoacrylate (for rapid bonding), polyurethane (for flexibility), and silicone (for environmental resistance).

Why is adhesive selection important in industrial applications?

Correct selection ensures safety, performance, and long-term reliability by matching adhesive properties to application-specific demands.

What methods are used for adhesive application?

Common methods include brush/roller (for precision), spray systems (for wide coverage), cartridges (for accuracy), and automated dispensing (for speed and consistency).

What are current trends in adhesive technology?

Key trends include eco-friendly formulations, smart adhesives with visual cues, and faster curing technologies that improve operational efficiency.

How are industrial adhesives tested?

Testing involves mechanical strength assessments (e.g., peel/shear), as well as simulations for heat, humidity, and material compatibility.

How can sustainability be integrated into adhesive use?

By selecting adhesives with low VOCs, reducing waste through recyclable packaging, and minimizing energy use in application processes.

Can adhesives match mechanical fasteners in industrial uses?

Yes, in many cases. Structural adhesives can rival or surpass mechanical fasteners, especially when bonding dissimilar materials or optimizing weight.

What’s the risk of improper adhesive application?

Improper application can lead to weak bonds, product failure, and increased maintenance costs. Following proper techniques is essential for safety and durability.